Zyvex Litho 1™

Sub-nm Resolution Lithography System

View brochure here

Making Atomic Precision Lithography a Reality

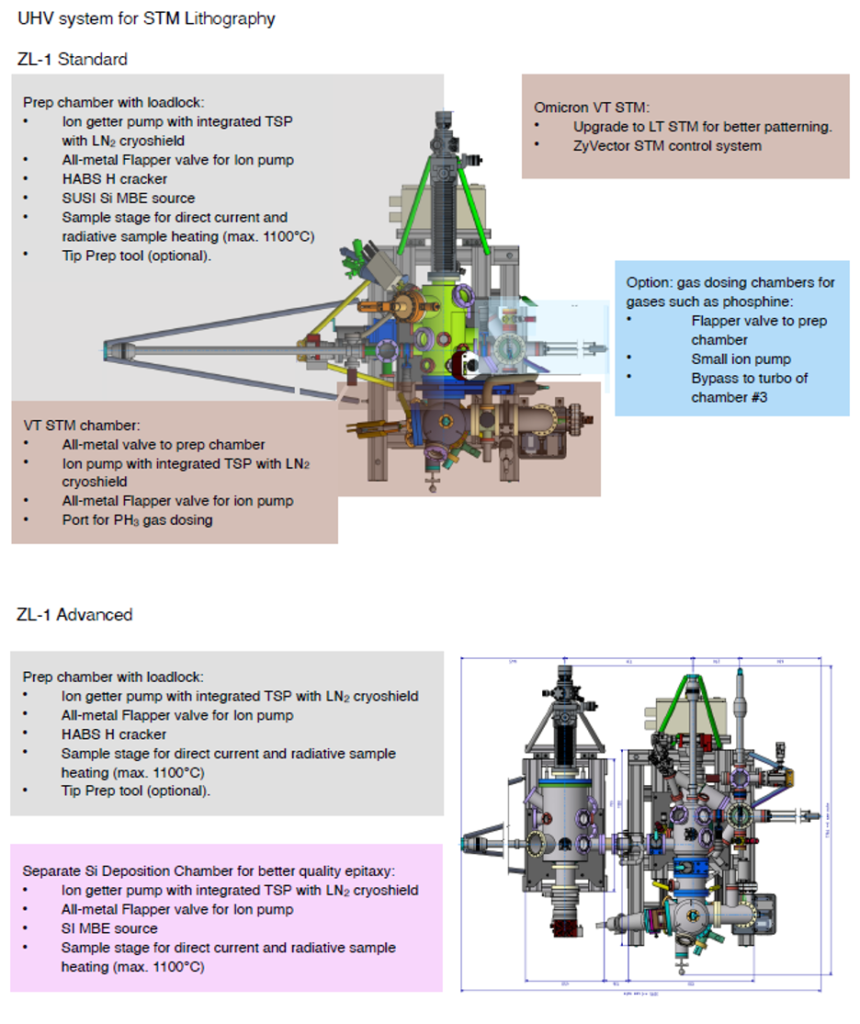

- UHV system for STM Lithography

- Precursor Gas Dosing and Si MBE

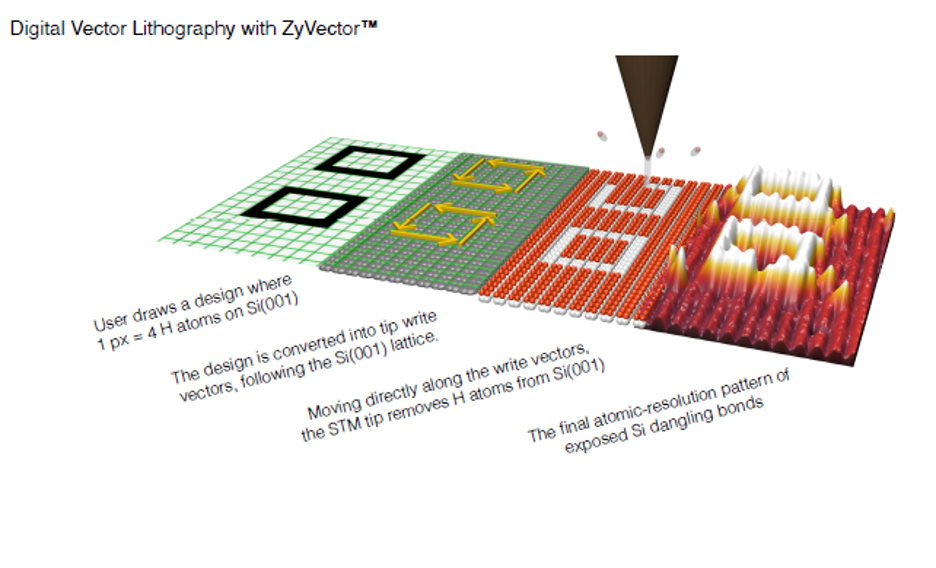

- Digital Vector Lithography

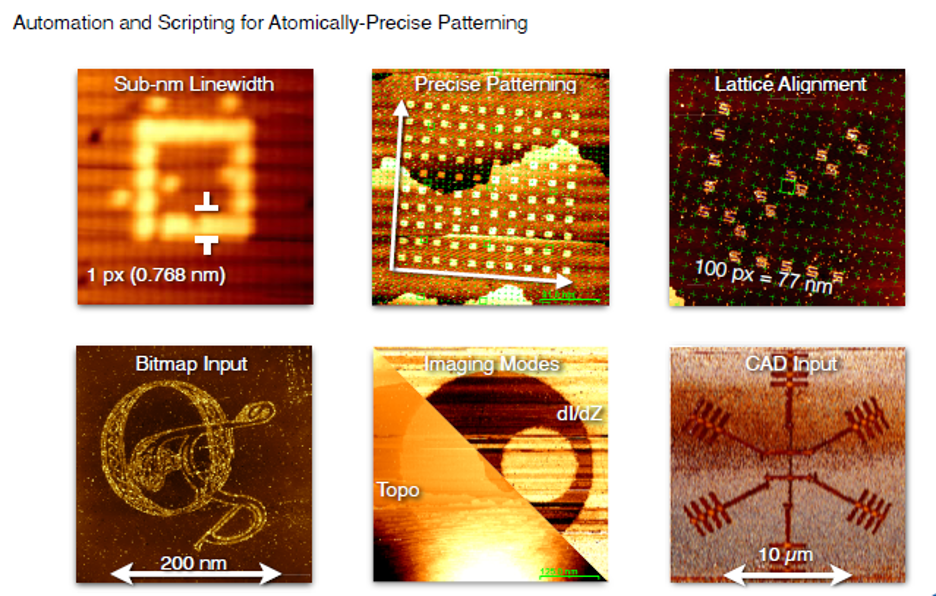

- Automation and Scripting

Technical Specifications:

ZyVector Lithography Controller

- 20-bit DSP

- Provides real-time control of the tunneling feedback loop and bias voltage. and precise tip motion across the surface.

- Piezo Driver

- Pre-amp bias range control for Omicron preamp amplified current input Fits Omicron VT STM preamp and PIC cabling.

Scanning

- Omicron VT STM: 9500 nm.

- Minimum scan bit size: 10 pm.

- Z range: 1.3 μm.

- Minimum bit size: 1 pm.

System Capabilities

- Heater station for Sample Preparation

- Si MBE source

- Precursor gas dosing chambers

Advanced Position Controls

- Local piezo tube calibration based on lattice recognition, including determination of lattice angle relative to piezo tube axes.

- Lattice phase recognition for precise lithography positioning.

- Creep and Hysteresis position correction (CHC) in xyz.

- Initial optimization of creep and hysteresis over scan range during installation. (Fine optimization by user required periodically.)

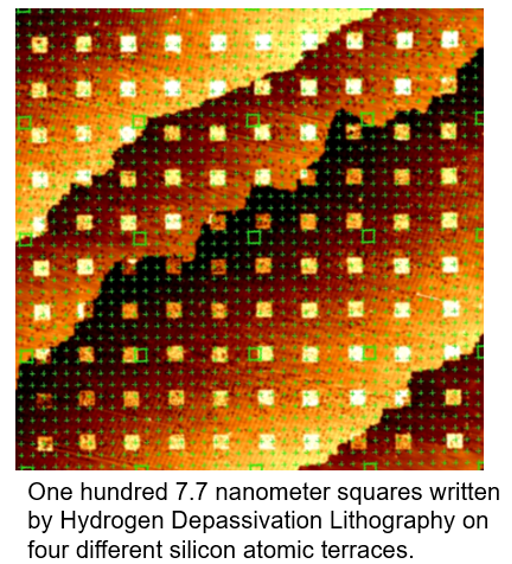

Hydrogen Depassivation Lithography (HDL)

- Two spot size modes available:

- AP mode ( single-dimer-row line width)

- FE mode ( wide line width, rough edges)

Advanced Scripting Capabilities

- We provide scripts based on Python for test HDL patterns, creep correction calibration, lithography parameter calibration, etc.

- User-written scripts can be easily incorporated and run using command line interface or drop-down menu.